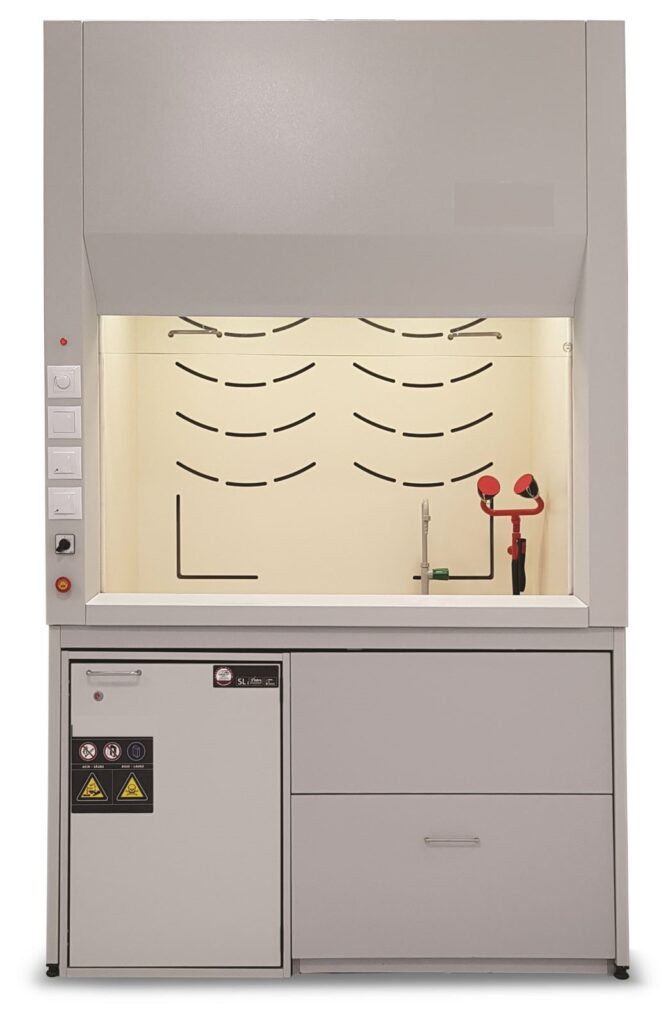

fume-cupboard-fume-hood

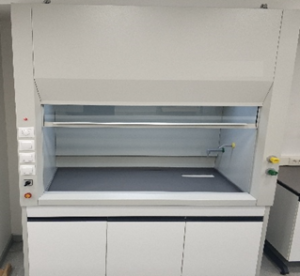

BS-EN-14175 certified fume cupboard, also known as fume hood; basically, is a local ventilation cabinet. Fume cupboard is designed to limit exposure to hazardous or toxic fumes & vapors in the laboratories, accordingly. Above all, fume hood is the essential device in a laboratory where chemical reactions are carried out. We have been a reputable fume hood manufacturer, in Turkiye, since 2006. Furthermore, wWe have a wide range of chemical fume hoods for R&D lab, QC lab, Educational & School lab or a third-party testing lab; likewise, you are all covered with our fume hoods.

BS-EN-14175-Certified-Fume-Cupboard

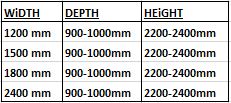

While selecting a fume hood the most obvious parameter that needs attention is the size and overall dimensions. Lab space availability and features, Type(s) of intended experimentation, Equipment setup needs, and finally Ease of working should help in determining the right size. Sizes usually indicate the overall width of the fume hood.

The chart below gives external fume hood dimensions. The standard working height is 900mm. For a low bench or a “walk-in” fume hood, it is 450- 600 mm. These are external dimensions and that the internal dimensions differ among manufacturers. Users must evaluate the internal useable area in consultation with manufacturers. Ducted fume hoods are re-locatable to an extent, but, not portable.

Finally, standard sizes need not be a limiting factor in procuring the right fume hood for a certain application. Competent manufacturers have the expertise to design and deliver bespoke (custom-made) fume hoods. Beyond fume hoods, there are special-purpose ventilated fume enclosures for odd needs. Neccessary fume ventilation must be technically assessed. make sure, the correct solution is used. We should remember that the single most important aspect is always, user safety.

Fume-cupboard-dimensions

Digital-fumehood-latest-model

Fume-cupboard

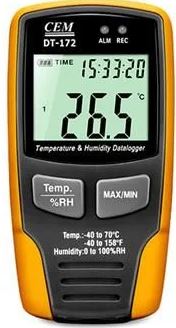

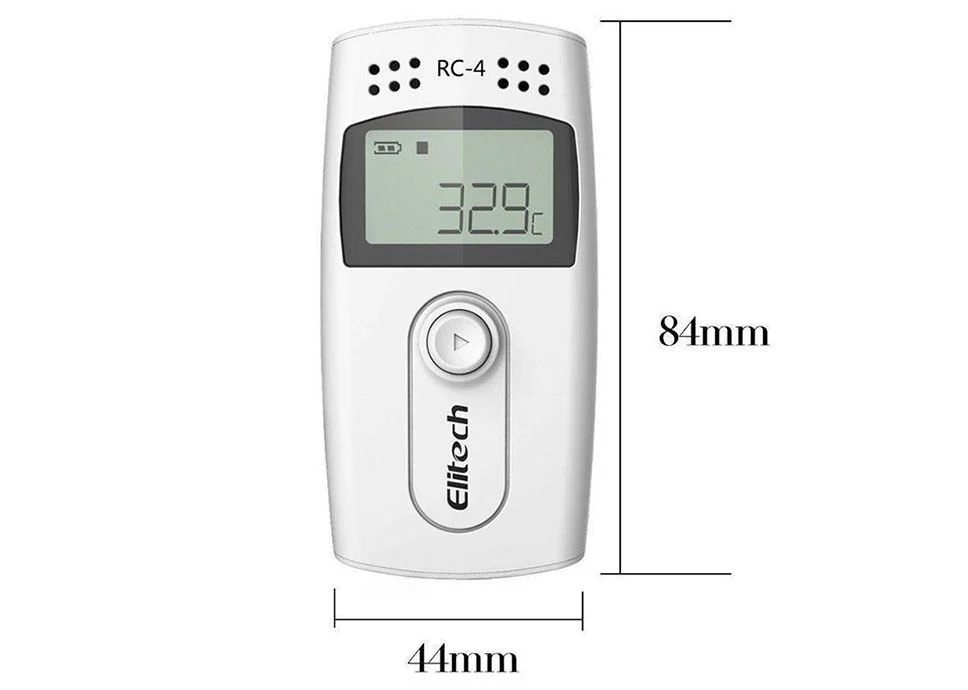

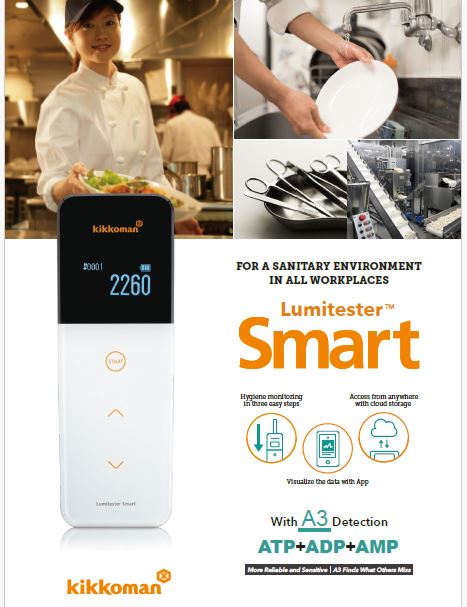

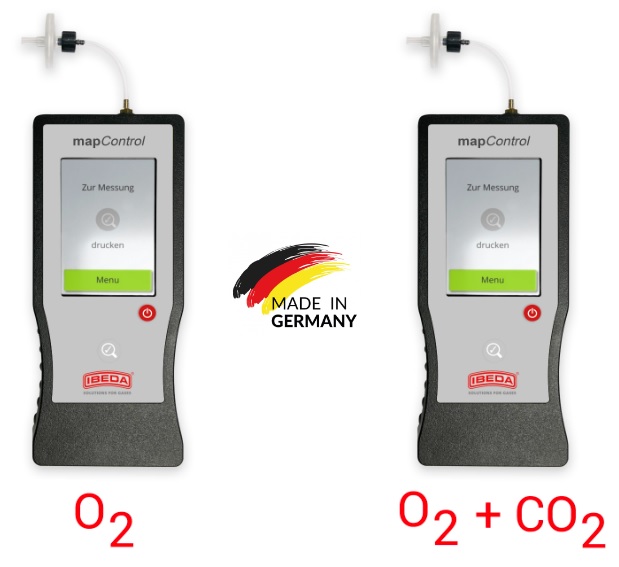

In general, main metal body of the fume cupboards are made in, epoxy powder coated steel. An acid resistant polypropylene fan should extract the acid fumes. Additionally, a chemical cupboard is placed under the worktop, without a doubt.

>Also, the correct material should be used on the fume hood, dependig on the purpose of point of use. These materials can vary between, Phenolic, HPL, PP, Acid Ceramic, Stainless steel for the work surface. a PP cup sink would be an useful accessory. Another key point, 6mm thick tempered glass is used as sash, for safety reasons.

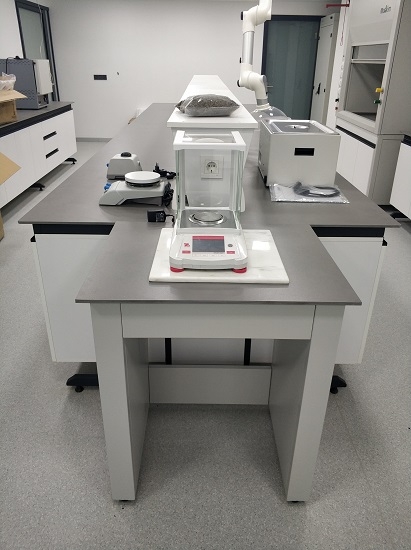

Fume-hoods-and-island-bench

Firstly, clean the interior and exterior surfaces and then afterwards lastly, sash, periodically. And after spills, using deionized water. Wipe the areas down, with a soap solution.

NOTE: Above all, make sure, you protect yourself from hazardous chemicals.

Firstly, please wear appropriate Personal Protection Equipment (PPE) then clean up the fume hood.

bespoke-fume-hood

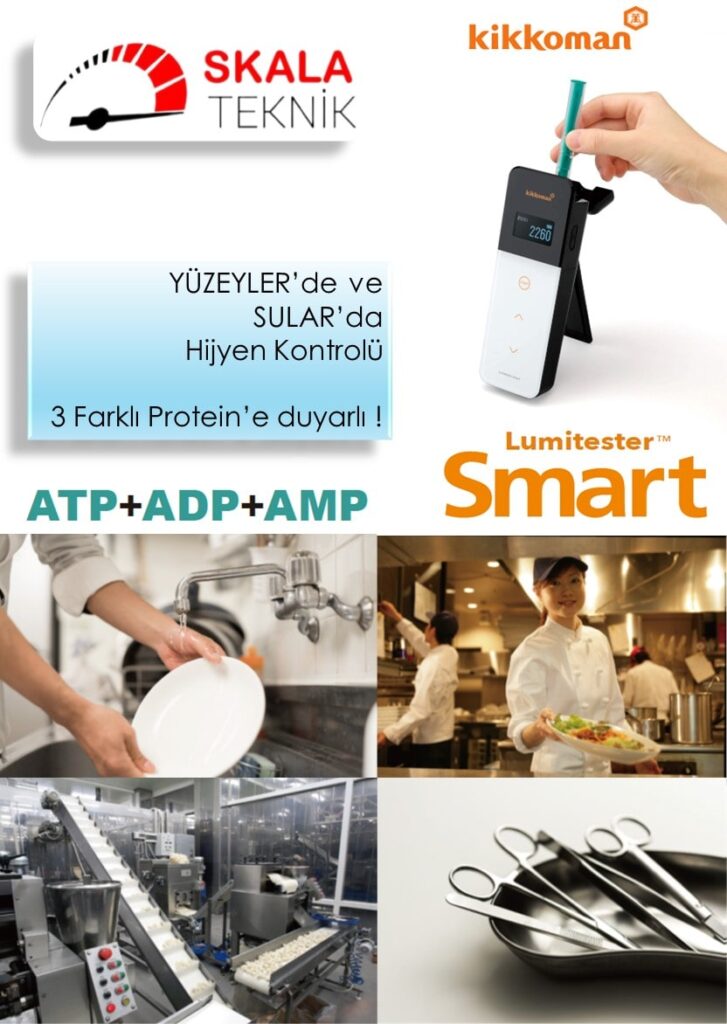

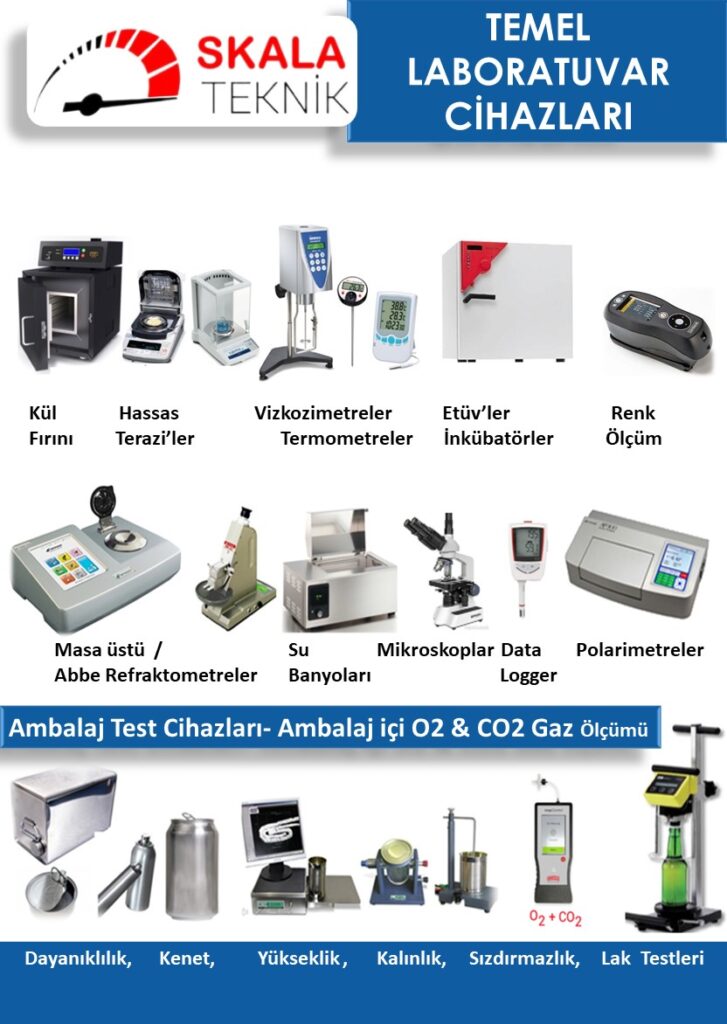

Skala Teknik

Typically replies within minutes

Any questions related to BS-EN-14175 CERTiFiED FUME HOOD – FUME CUPBOARD – WALK-iN – ATEX – POLYPROPYLENE PP – BESPOKE – CUSTOM MADE FUME HOOD?

WhatsApp Us

🟢 Online | Privacy policy